| 加工定制 | 是 |

|---|---|

| 类型 | 一体式 |

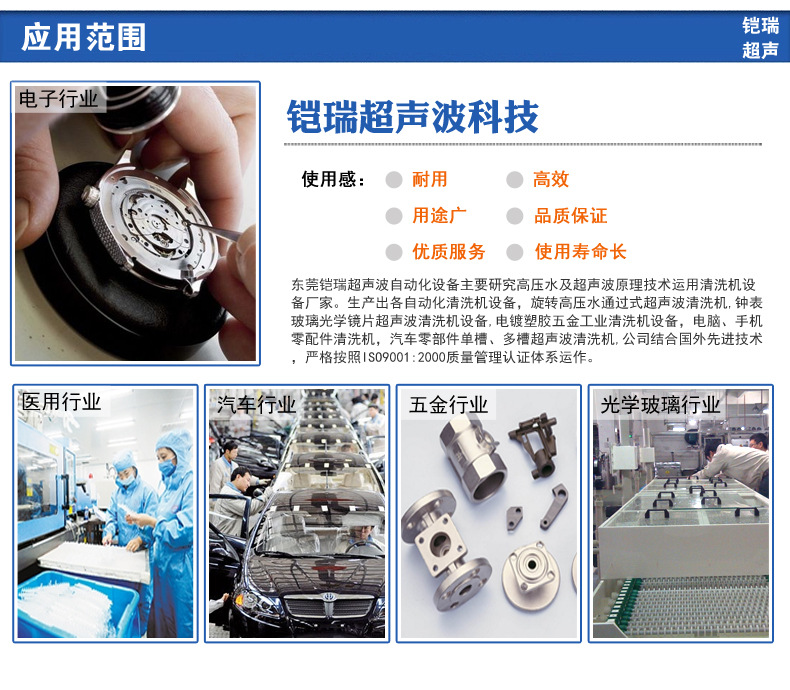

| 适用领域 | 五金行业 |

| 用途 | 工业用 |

| 槽数 | 2 |

| 超声清洗频率 | 28-40KHZ |

| 清洗温度 | 0-100(℃) |

| 工作方式 | 超声波 |

| 功率 | 大功率4500W |

| 品牌 | 铠瑞 |

| 型号 | KR-012-46ZDF |

产品特点:

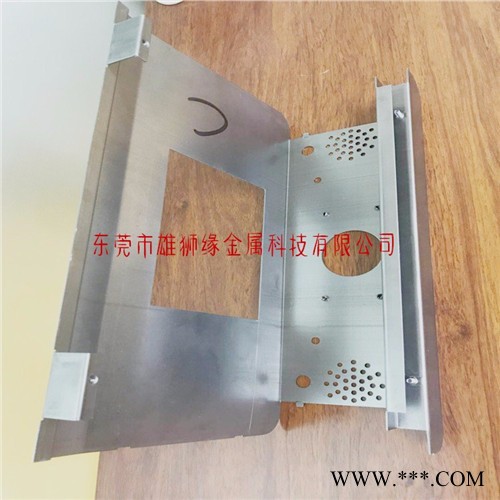

槽体采用进口不锈钢制造,耐酸耐碱,外形美观大方。

采用进口**高Q值换能器和独特的超声发生器,超声波输出强劲有力。

采用日本进口粘接剂和独特粘接工艺,确保换能器在100℃水温长时间工作,经久耐用。

设有自动温控加热装置,温控范围:常温-100℃。

超声波发生器和缸体分体结构,采用高频线座连接,使用及保养方便。

超声波发生器采用目前国际**的他激式震荡线路结构,较传统的自激式震荡线路结构在输出功率增加15%以上,能**限度的发挥换能器的潜能。工作电压AC220±10V。具有过压,过流,输出短路等保护措施。有频率微调、频率自动跟踪的功能,在不同工况下都能达到**效果。带动清洗液形成细微回流,使工件污垢在被超声剥离的同时迅速带离工件表面,提高清洗效率。具有功率无级调节的功能,输出功率可实现10%——**的连续调整,以适应各种清洗对象的要求,还可设定时间定时,安全操作。

适用范围:

1 机械行业:防锈油脂的去除;量具的清洗;机械零部件的除油除锈;发动机、化油器及汽车零件的清洗;过滤器、滤网的疏通清洗等。尤其在铁路行业,对列车车厢空调的除油去污、对列车车头各部件的除锈、除油、防锈,非常适合。

2 表面处理行业:电镀前的除油除锈;离子镀前清洗;磷化处理;清除积炭;清除氧化皮;清除抛光膏;金属工件表面活化处理等。

3 仪器仪表行业:精密零件的高清洁度装配前的清洗等。

4 电子行业:印刷线路板除松香、焊斑;高压触点等机械电子零件的清洗等。

售后服务:

5 设备终验收合格后12个月为质量保证期,质保期内在正常使用下如设备发生故障,应及时进行无偿修理,修正。

6 试生产因设备或工艺的原因所发生问题由卖方负责迅速解决。

7 保修期内,本公司的保修不包含以下事项:

未经供应公司书面同意,用户安排其他厂商或客户自行对设备工零件更换、维修或移动。

任何意外或天灾等不可抗力事件造成设备损坏,或非公司人员因疏忽或处理不当造成之设备损坏。

Product features:

The tank made of imported stainless steel, acid and alkali resistant, beautiful appearance.

The use of imported high quality Q transducer and unique ultrasonic generator, ultrasonic power output.

The use of Japanese imported adhesive and unique bonding process, to ensure that the temperature of the transducer at 100 water temperature for a long time to work, durable.

With automatic temperature control heating device, temperature range: -100.

Ultrasonic generator and cylinder block structure, the use of high frequency line connecting, use and maintenance convenience.

Ultrasonic generator adopts the current international leader in shock line structure, compared with the traditional self excited vibration circuit structure in the output power increased by more than 15%, can maximize the potential of the transducer. Working voltage AC220 + 10V. Protection measures such as over voltage, over current, short circuit and so on. With the function of frequency adjustment and frequency automatic tracking, the best results can be achieved under different operating conditions. Lead to the formation of a fine return of the cleaning fluid, so that the workpiece dirt in the ultrasonic stripping and quickly brought out of the workpiece surface, improve the cleaning efficiency. With the function of stepless adjustment of power, the output power can be realized by 10% - ** continuous adjustment, in order to meet the requirements of various cleaning objects, but also can set time, safe operation.

Applicable scope:

1 Machinery Industry: removal of rust preventive oils; measuring cleaning; machinery parts and components of the oil and rust removing; engine, carburetor and automotive parts cleaning; filter, filter dredging and cleaning. Especially in the railway industry of air conditioning train except oil decontamination, the rust of the components on the front of the train, degreasing, rust, very suitable for.

2 surface treatment industry: before electroplating degreasing and derusting; ion plating before cleaning; phosphating; removal of coke; removing oxide skin; remove polishing paste; metal workpiece surface activation treatment.

3 instruments and meters industry: the precision parts of the clean assembly before the cleaning, etc..

4 electronics industry: printed circuit board in addition to rosin, welding spot; high voltage contact and other mechanical and electronic parts cleaning, etc..

After-sale service

12 the final acceptance of the equipment for 5 months for the quality assurance period, the quality of the warranty period, such as the normal use of equipment failure, should be carried out in a timely manner to repair, modify.

6 to produce the equipment or process for the reason of the problem by the seller is responsible for rapid settlement.

7 under the warranty period, the company's warranty does not include the following:

Without the written consent of the supplier, the user can arrange for other manufacturers or customers to change, maintain or move the equipment parts.

Any accidents or natural disasters, such as force majeure event causing damage to the equipment, or non company personnel due to negligence or improper handling equipment damage.